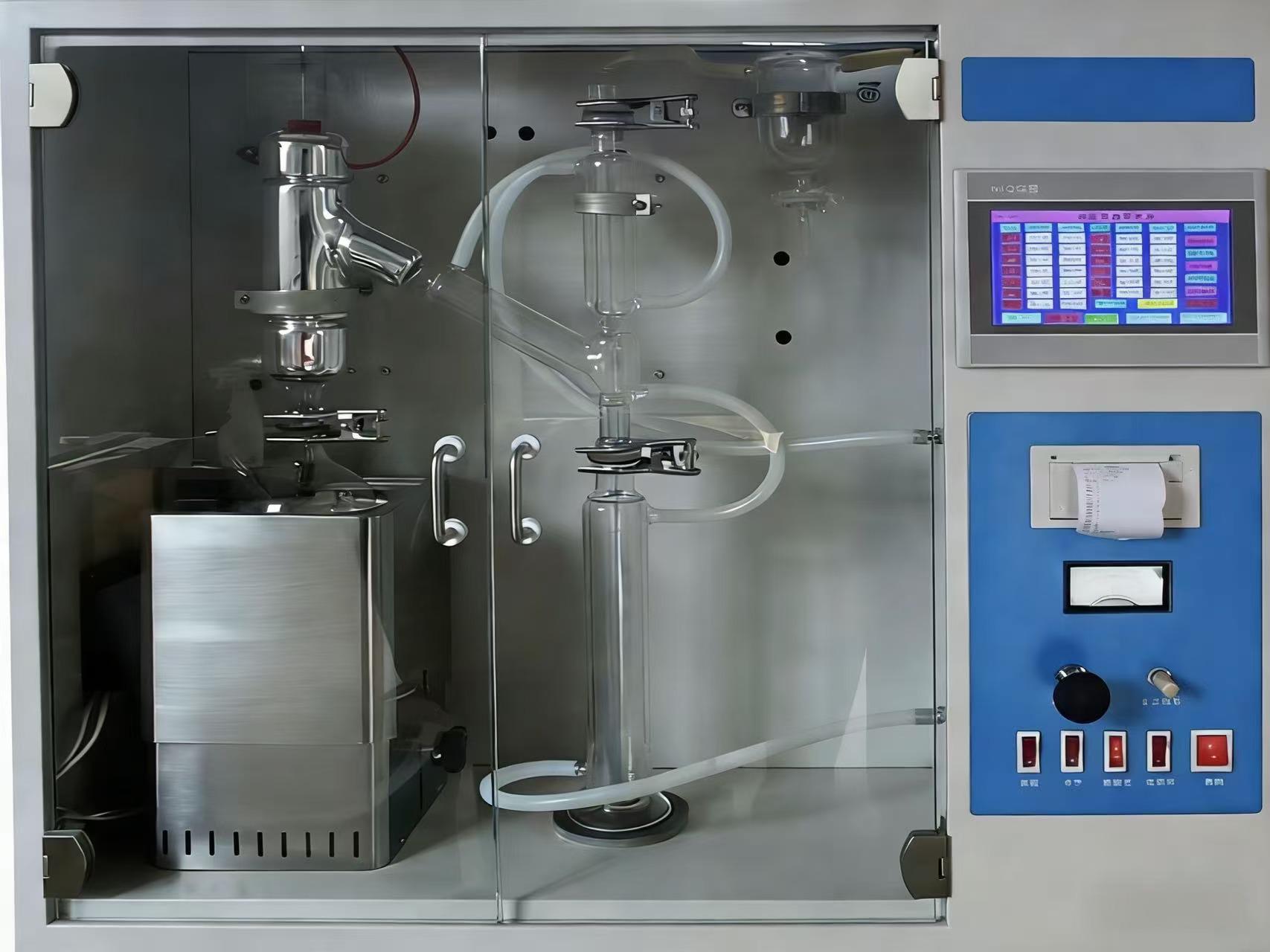

Aviation Kerosene Lubricity Tester

- DOOWAY

- Shanghai

- 30days

- 50set/Month

The Aviation Kerosene Lubricity Tester is specifically designed to evaluate the lubricating properties of aviation fuels, particularly jet fuels. Using a standard steel ball and a standard test ring to create controlled friction, the instrument measures the size of the wear scar formed on the steel ball. This measurement provides an accurate assessment of the boundary lubrication performance of the fuel.

Operating Principle

The system is composed of two main sections: an electronic control module and a mechanical testing module. The electronic control module incorporates a microprocessor controller that provides fully automated regulation of oil bath temperature, test cycle, air humidity, and airflow. All core control units and key components are sourced from premium imported manufacturers to ensure reliability and precision.

During testing, the sample is placed in the sample chamber, where relative humidity is maintained at 10%. A test steel ball is mounted vertically in a chuck and positioned directly against an axially mounted test steel ring, with a specified load applied. The steel ring is partially immersed in the test sample and rotates at a constant speed, creating friction with the steel ball under wetted fuel conditions. After the designated test period, the wear scar diameter on the surface of the steel ball is examined under a reading microscope. This measurement is then used to determine the lubricity of the aviation kerosene sample with high accuracy.

Technical Specifications

1. Standards Compliance: Fully conforms to ASTM D5001-2023 (Normative Appendix A2, Fully Automated Method) and SH/T 0687 requirements.

2. Sample Volume: 50 mL±1.0 mL.

3. Test Load: 1000 g (including a 500 g weight)±1 g, with automatic loading.

4. Sample Temperature: 25±1°C.

5. Airflow Rate: 3.8±0.05 L/min.

6. Air Humidity: Maintains relative humidity at 10±0.2% at 25±1°C, automatically controlled.

7. Sample Pretreatment: A 0.5 L/min airflow is introduced into the sample while a separate 3.3 L/min stream passes over the sample surface for 15 minutes. Airflow and humidity are automatically regulated using mass flow controllers.

8. Test Conditions: During testing, air passes over the sample surface at 3.8 L/min, with automatic adjustment via mass flow controllers.

9. Test Duration: 30±0.1 minutes.

10. Ring Rotation Speed: 240±1 r/min.

11. Wear Scar Measurement System: Equipped with a metallographic microscope (100x magnification) with X/Y dual-axis measurement, precision to 1 μm. Integrated video display system for intuitive observation. Includes dedicated computer and software for image storage, data management, and generating editable, printable test reports.

12. Digital Micrometer: X/Y dual-axis digital micrometer, precision to 1 μm.

13. Test Ring: Meets requirements of SH/T 0687, Section 7.1.1.

14. Test Ball: Meets requirements of SH/T 0687, Section 7.1.3.

15. Reference Fluids: High reference fluid A and low reference fluid B, fully compliant with SH/T 0687 standards.