General Petroleum Product Analysis

-

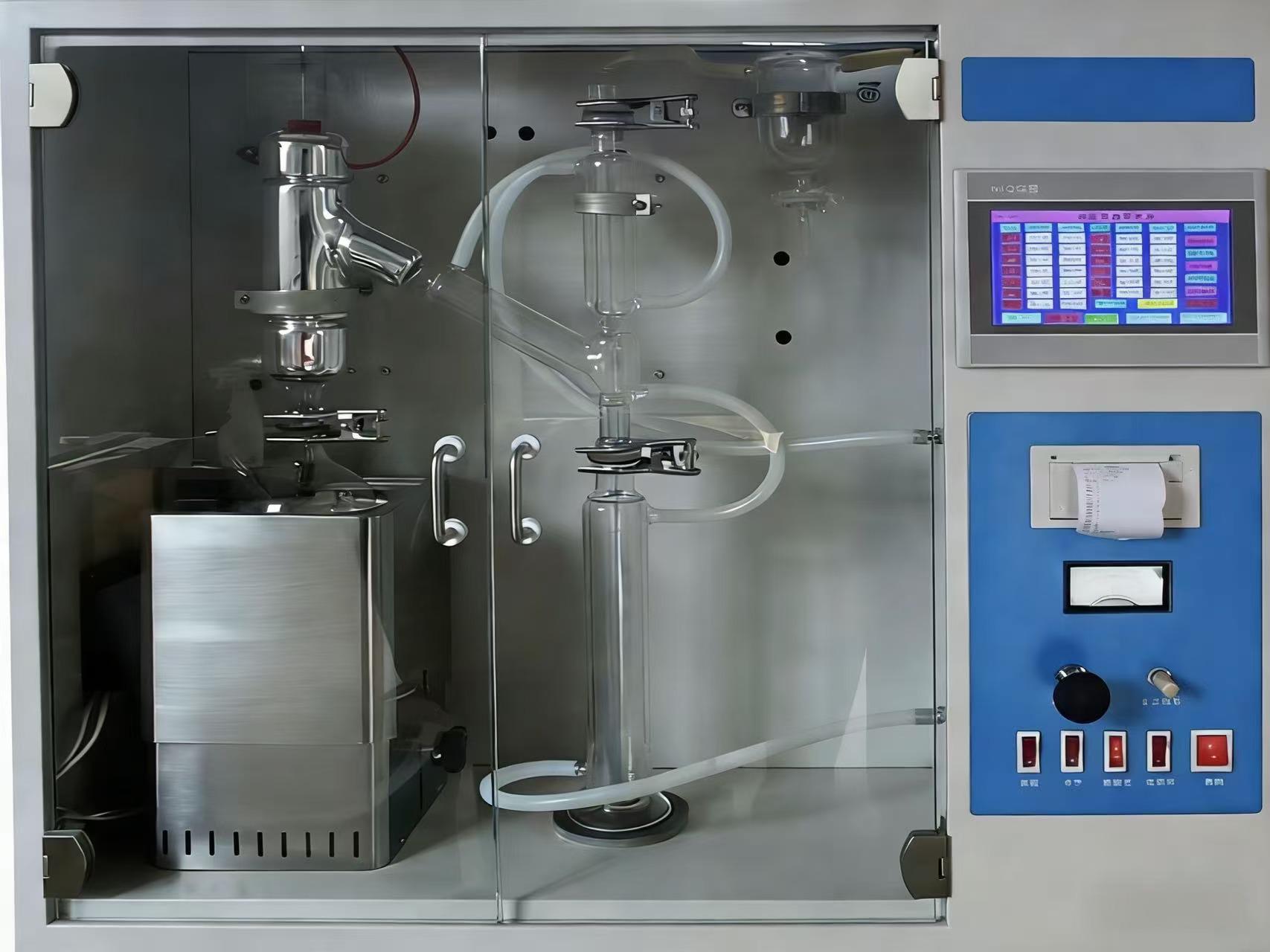

Aviation Kerosene Lubricity Tester

The Aviation Kerosene Lubricity Tester is specifically designed to evaluate the lubricating properties of aviation fuels, particularly jet fuels. Using a standard steel ball and a standard test ring to create controlled friction, the instrument measures the size of the wear scar formed on the steel ball. This measurement provides an accurate assessment of the boundary lubrication performance of the fuel.

Email Details

Operating Principle

The system is composed of two main sections: an electronic control module and a mechanical testing module. The electronic control module incorporates a microprocessor controller that provides fully automated regulation of oil bath temperature, test cycle, air humidity, and airflow. All core control units and key components are sourced from premium imported manufacturers to ensure reliability and precision.

During testing, the sample is placed in the sample chamber, where relative humidity is maintained at 10%. A test steel ball is mounted vertically in a chuck and positioned directly against an axially mounted test steel ring, with a specified load applied. The steel ring is partially immersed in the test sample and rotates at a constant speed, creating friction with the steel ball under wetted fuel conditions. After the designated test period, the wear scar diameter on the surface of the steel ball is examined under a reading microscope. This measurement is then used to determine the lubricity of the aviation kerosene sample with high accuracy. -

automatic vacuum distillation tester

● The instrument features a 7-inch industrial-grade touch screen, which provides real-time display of steam temperature, electric furnace temperature, and water bath temperature.

Email Details

●The instrument adopts a PLC controller, ensuring stable control and convenient operation.

●Imported high-precision sensors are used to collect sample temperature data, ensuring high measurement accuracy

●The instrument features high automation, allowing users to input the corresponding recovery volume by clicking on the screen. It automatically saves the test results and performs automatic atmospheric and vacuum pressure conversion. It can record the initial boiling point, the range from 10% to 90%, and the final boiling point. -

Fully automatic kinematic viscosity tester

DP1003BZ automatic viscosity instrument complies with GB/T265-88 A product that meets the requirements of ASTM D445, D446, ISO3104, and ISO3105 Regulations for determining transparent and opaque liquids, including crude oil, light and heavy fuels .The kinematic viscosity of feed oil

Email Details -

Electric vehicle coolant corrosion simulation test bench DW512

Instrument Overview

Email Details

With the rapid expansion of the new energy vehicle market, vehicle antifreeze has also ushered in unprecedented development opportunities. The strong development momentum of new energy vehicles will have a profound impact on the coolant industry. With the popularization of new energy vehicles and the advancement of technology, the performance and quality requirements for coolants will continue to improve, bringing new challenges and opportunities to the coolant industry.

New energy vehicles have extremely high requirements in terms of temperature control and management of in-vehicle heat sources, mainly involving heat source components such as batteries, controllers and motors. At present, liquid cooling has become the mainstream heat dissipation method for new energy vehicles because it is not only safe, but also has significant heat dissipation effect. Compared with traditional fuel vehicles, new energy vehicles have significantly increased the use of coolant. The safety and reliability of electric vehicle coolant are crucial to ensuring the normal operation of electric vehicles. The corrosion test bench for electric vehicle coolant developed by our company can play a positive role in promoting in many fields, improving product quality and protecting consumer rights and interests.

The test bench can simulate the actual operating conditions (temperature, flow and loop environment) of the coolant in typical application scenarios of automobile operation, automatically operate during the test time, and automatically monitor the pH value, conductivity and other parameters of the coolant during operation. Change status and trends. Samples can be taken for ion composition analysis. The test bench can solve problems such as complicated manual steps, many human factors, and inaccurate data during the test process, improve work efficiency and ensure the safety of testers. -

Corrosion simulation test bench for proton exchange membrane fuel cell coolant DW510

The test bench can simulate the actual operation of coolant (temperature, flow rate and environment) in the most typical application scenarios of proton exchange membrane fuel cell (PEMFC), and run automatically in a long simulation time, and the loop can automatically monitor the change and trend of pH value, electrical conductivity and freezing point during operation, and can sample for ion composition analysis. The test bench will solve the problems of complicated manual steps, many human factors and inaccurate data in the test process, and improve the work efficiency and ensure the test personnel.

Email Details

DW510 simulates the application scenario of proton exchange membrane cell as fuel cell generator according to its practical application environment, which is also the largest, most meaningful and most typical application scenario of proton exchange membrane fuel cell at present and in the future. -

Hot

High frequency reciprocating test machine for evaluating diesel lubricity DP6079

Product characteristics:

Email Details

Temperature and humidity control system integrated design, simple and generous, simple operation, small space saving, high control accuracy.

The control box is equipped with a key start, the experiment process without manual intervention. -

Monochromatic Wavelength Dispersive Fluorescence Spectrometry

X ray Monochromatic Wavelength of Petroleum Product Overview

Determination of sulfur and chlorine content in products (X-ray spectrometry) the trace sulfur content of petroleum products was determined according to the standard: ASTM D4294, and the trace chlorine content of petroleum products was determined according to the standard SH/T0161, ASTM D4929line ASTM D7536 and ISO 15597.

Because X ray Dispersive Fluorescence Spectrometry of Petroleum Product adopts physical analysis method, X ray Dispersive Fluorescence Spectrometry of Petroleum Product has the characteristics of fast analysis speed, no complex sample pretreatment, high precision, small human error, low labor intensity of operators, no pollution and so on.

Therefore, X ray Monochromatic Wavelength of Petroleum Product has been widely used in the world and basically replaced other analytical methods for sulfur determination.X ray Monochromatic Wavelength of Petroleum Product X ray Dispersive Fluorescence Spectrometry of Petroleum Product ASTM D4294Email Details -

Auto Fluorescent UV Sulfur Tester

Auto Fluorescent UV Sulfur Tester Overview

Auto Fluorescent UV Sulfur Tester DP500T meets the requirements of ASTM D5453, D6667, D7183, GB/T 34100-2017, GB/T35582, GB/T11060.8, SH/T 0689, ISO 17198 and DB51/T 1689 standards. Determination of trace sulfur in liquid samples is used to detect the content of trace sulfur in liquid samples.

Ultraviolet fluorescence analysis technique is used in petroleum, petrochemical, chemical and environmental protection fields. Coal Sulfur Tester can be used to determine the total sulfur content in gasoline, diesel, crude oil, distillate oil, hydrocarbon and engine fuel, petroleum gas, petrochemical products and coal, Meet the analysis requirements of sulfur content in gasoline (National V) and diesel (National IV).Auto Fluorescent UV Sulfur Tester Coal Sulfur Tester UV Ultraviolet Fluorescence Sulfur in Oil TesterEmail Details -

Hot

Automotive Gasoline Combustion Power Performance Quantitative Analysis Test Platform

Instrument design background

Email Details

With the diversification of sources and blending technologies of automotive gasoline, the differences in the components of automotive gasoline with the same brand but different sources are also increasing. As a result, the quality of combustion power generation varies, and currently, there is still a lack of inspection, testing, and measurement standards for the combustion power generation of automotive gasoline.

This has caused many car gasoline products to meet ASTM or national standards, but there is a problem of gasoline being "not burn resistant" in actual use by car owners, and it is also difficult to control and supervise the quality differences in the actual application of car gasoline, seriously affecting consumer rights.

It has great guiding significance and promoting effect on the level of oil adjustment for refineries and oil product manufacturers. Compared to different manufacturers, the higher the combustion power and durability of the gasoline produced for vehicles, the better the quality of the oil, and the higher the sales volume of the oil. When retail to gas stations, the greater the refueling flow for car owners.